|

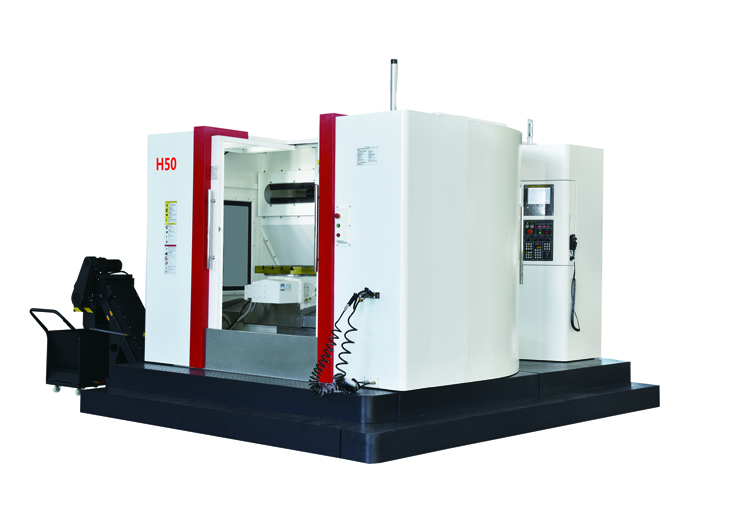

H50 Horizonal Machining Center The cross structure

Characteristics Adopting the inverted T-shaped moving column design developed by R&D,the overall bed structure has high rigidity and good stability;The castings arecast using resin sand molds, with high accuracy retention;The standard BT50ring spray spindle is equipped with an air curtain protection device, completelyavoiding the infiltration of cutting fluid and dust;Cooling of the spindle sleevereturn oil ensures spindle accuracy and extends service life;The machine isequipped with a dual spiral chip conveyor and an automatic chain chip removaldevice. The cutting flushing device can automatically discharge the cutting in atimely manner, avoiding the thermal impact of cutting on the machine tool andensuring high precision of machining;The screw adopts a fixed pre stretchedstructure at both ends, which eliminates transmission clearance and thermaldeformation, improves transmission accuracy, and the screw bearing is lubricated with thin oil;Each axis guide railadopts imported heavy-duty roller linear guide rails, with a preload of V3 level, high load-bearing capacity, and stable accuracy;The B-axis is equipped with a indexing workbench with a mouse tooth disc (1°x 360) as standard, which has high positioning accuracy;CNC workbenches with continuous indexing(0.001°)positioning can also be optionally equipped;The exchange platform adopts a novel rotating push-pull structure. Rotating actionUsing servo motor drive, the push-pull action adopts oil cylinderDrive, exchange balance, accuracy, and reliability; Capable of milling, boring, drilling (drilling, expanding, hinge) Multiple processing functions such as threading and spot milling, product qualityStable quality, high machine torque, excellent quick response characteristics,Suitable for automobiles, molds, aerospace,warehousingRequirements for various mechanical processing fields such as hardware. |